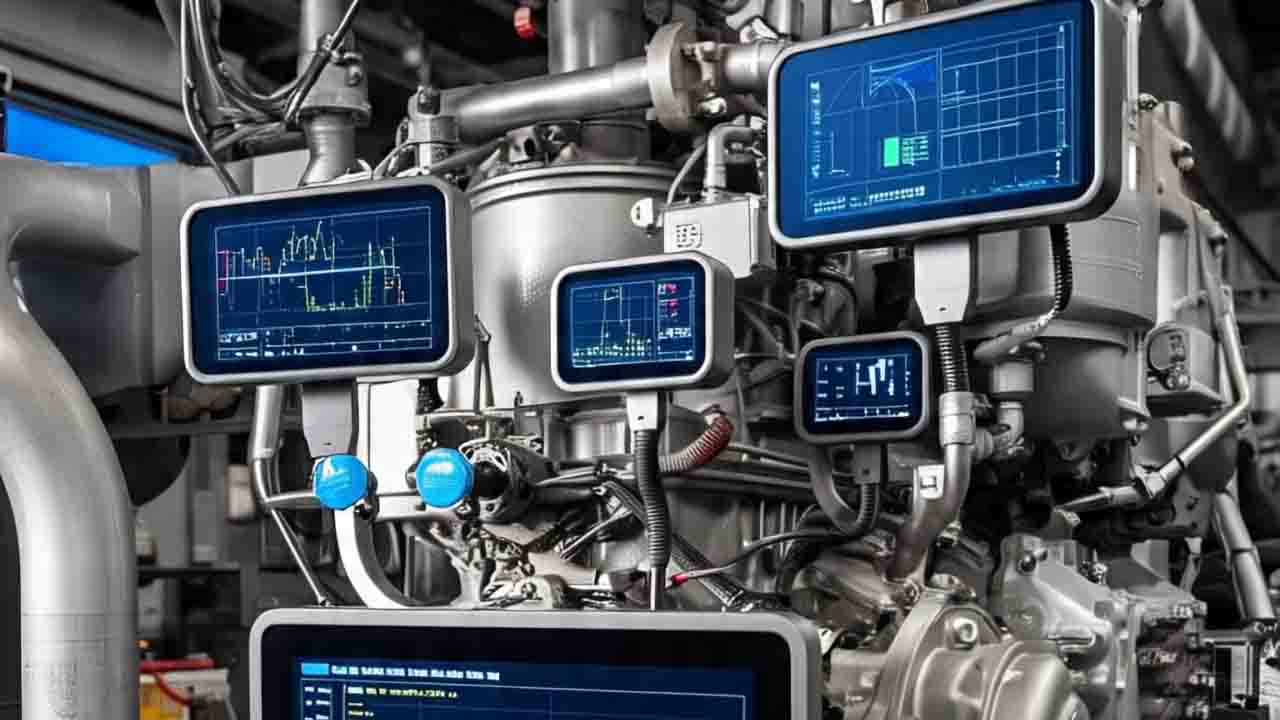

Dieselspecialists – AI Predicts Before any failure occurs, changing the landscape of diesel engine maintenance forever. The integration of Artificial Intelligence (AI) and the Internet of Things (IoT) has enabled a shift from reactive to predictive maintenance, which anticipates issues before they cause costly downtime. By constantly monitoring engine performance data through connected sensors, AI algorithms analyze patterns and detect anomalies early. This proactive approach not only prevents unexpected breakdowns but also maximizes the operational efficiency of diesel vehicles across industries.

The ability of AI to predict problems ahead of time is critical for sectors such as logistics, transportation, and construction, where diesel engines play a pivotal role. This technology drastically reduces repair costs and extends the lifespan of machinery by allowing timely intervention based on real-time insights.

AI Predicts Before mechanical failures disrupt vehicle operation by leveraging vast amounts of data collected from IoT-enabled devices embedded in diesel engines. These smart sensors continuously gather information on temperature, pressure, vibration, and other vital metrics. Advanced machine learning models process this data to forecast potential malfunctions and alert maintenance teams instantly.

“Kawasaki Eliminator 2025: A Bold Cruiser Look”

This real-time predictive capability helps fleet managers schedule maintenance more effectively, minimizing unplanned downtime and ensuring smoother workflows. AI Predicts Before a minor issue escalates into a major fault. Which means vehicles spend less time off the road and more time in productive use. The shift toward predictive maintenance represents a new standard in reliability and operational resilience.

AI Predicts Before traditional maintenance methods can react, providing significant benefits beyond just operational uptime. By catching faults early, this technology supports more efficient use of resources. Reducing waste associated with emergency repairs and part replacements. Furthermore, predictive maintenance powered by AI and IoT contributes to environmental sustainability by optimizing fuel consumption and lowering emissions through well-maintained engines.

The financial advantages are equally compelling. Businesses adopting AI-driven predictive maintenance experience lower maintenance costs and improved return on investment due to fewer breakdowns and prolonged engine life. As AI Predicts Before breakdowns become the norm. The diesel engine industry is poised to enter a new era defined by smarter, greener, and more cost-effective maintenance practices.

“The Return of Face to Face: Rebuilding Community”

[SITE_NAME] - off highway diesel engine technology is evolving rapidly to meet stringent emissions standards and increasing demands for fuel…

[SITE_NAME] - alternative fuels changing diesel engines are accelerating the evolution of transportation technology as industries shift toward cleaner and…

Diesel Specialists | Expert Engine Solutions for Diesel, Gasoline & More - Diesel particulate filter failures on Komatsu heavy equipment…

Diesel Specialists | Expert Engine Solutions for Diesel, Gasoline & More - A common rail diesel engine significantly enhances fuel…

Diesel Specialists | Expert Engine Solutions for Diesel, Gasoline & More - heavy duty diesel engines different characteristics set them…

Diesel Specialists | Expert Engine Solutions for Diesel, Gasoline & More - Properly inspect your diesel engine before a long…