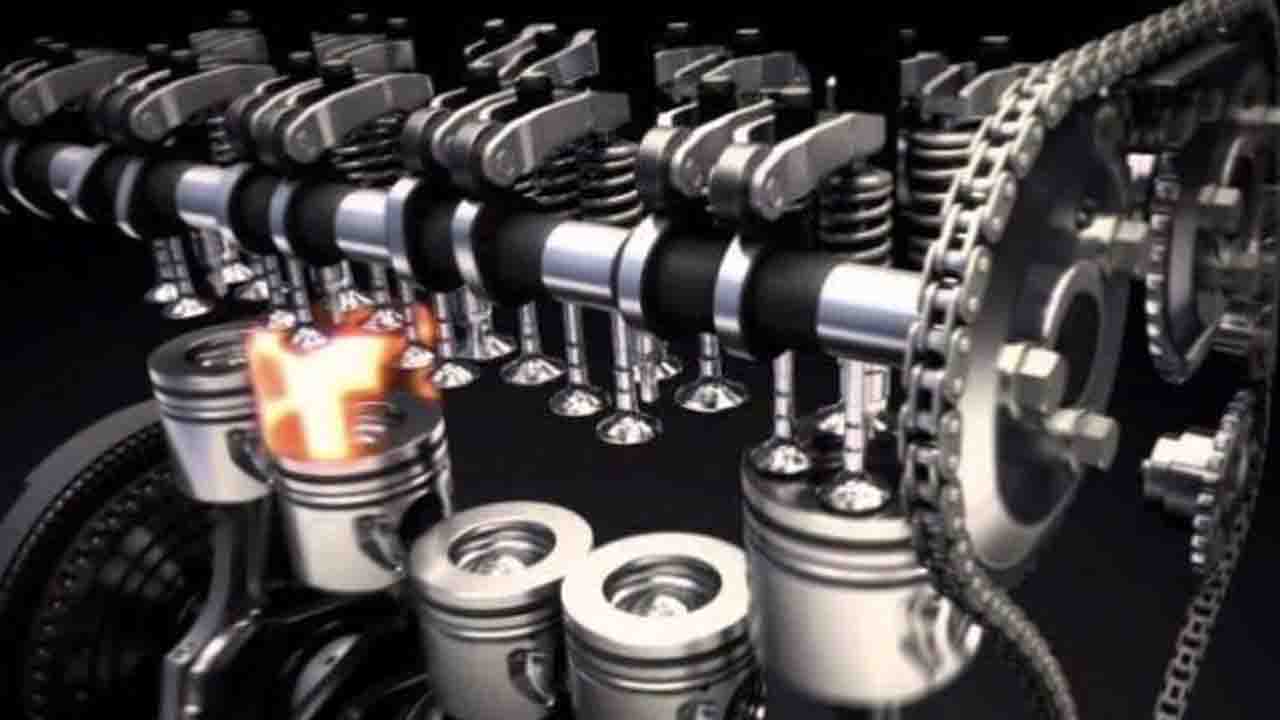

Dieselspecialists – Precision matters when it comes to diesel engine performance, and one of the most critical factors is the calibration of the fuel injection pump. Proper calibration ensures that diesel fuel is delivered to the combustion chamber at the exact right time, in the correct quantity, and with precise atomization. This process directly impacts fuel efficiency, engine power, and overall performance. By focusing on precise injection pump settings, mechanics and engineers can unlock the full potential of diesel engines while reducing fuel waste and emissions.

“Exploring Laos on Two Wheels: Waterfalls and Highlands”

Precision matters in the injection system because even minor deviations can affect engine efficiency. The injection pump controls the timing and pressure of fuel delivery, which determines how effectively the fuel mixes with air in the combustion chamber. If the pump is misaligned, engines may experience incomplete combustion, reduced power output, higher fuel consumption, and increased emissions. By carefully calibrating the injection pump, technicians can ensure that the engine operates smoothly, maximizes energy output, and maintains optimal fuel economy.

Precision matters during the calibration process, which typically involves measuring injection timing, adjusting fuel quantity, and testing pressure outputs under various engine loads. Modern diesel engines often utilize electronic control units (ECUs) that allow for fine-tuning injection timing with high accuracy. Mechanics may also use diagnostic tools to simulate different operating conditions. Ensuring that the fuel pump delivers consistent performance across all scenarios. Properly calibrated pumps not only improve efficiency. But also extend engine life by reducing wear and tear caused by improper fuel delivery.

When the injection pump is accurately calibrated, diesel engines benefit in multiple ways. Engines consume less fuel, produce higher torque, and run more reliably, even under heavy loads. Additionally, precise fuel injection reduces harmful emissions, contributing to a cleaner environment. Vehicle operators can also enjoy lower maintenance costs due to smoother engine operation and reduced component stress. Ultimately, prioritizing injection pump calibration demonstrates that precision matters not only for performance. But also for sustainability and cost-effectiveness in the diesel industry.

“Nadiem Makarim Detained Over Laptop Corruption”

Diesel Specialists | Expert Engine Solutions for Diesel, Gasoline & More - The global diesel engine market outlook is entering…

Diesel Specialists | Expert Engine Solutions for Diesel, Gasoline & More - Pemilik mobil diesel yang mengejar performa sering mengandalkan…

Diesel Specialists | Expert Engine Solutions for Diesel, Gasoline & More - Major engine makers and fleet operators are accelerating…

Diesel Specialists | Expert Engine Solutions for Diesel, Gasoline & More - Persaingan otomotif global kini berputar pada performance emissions…

Diesel Specialists | Expert Engine Solutions for Diesel, Gasoline & More - Fleet owners and individual drivers increasingly realize that…

Diesel Specialists | Expert Engine Solutions for Diesel, Gasoline & More - Beginner drivers increasingly try a basic diesel engine…