Smart Sensors and IoT in Modern Diesel Engines

Dieselspecialists – Diesel engines have always been symbols of strength and endurance. For decades, they powered farms, mines, highways, ports, and construction sites through pure mechanical force. However, a major shift is happening. Today, diesel engines are not only powerful they are intelligent. This evolution is driven by Smart Sensors IoT Diesel technology, turning heavy machines into connected smart systems capable of predicting failures, saving fuel, and improving performance with real-time data.

In earlier generations, diesel technicians listened to the sound of an engine, watched smoke color, and felt vibrations to diagnose issues. While those skills remain valuable, modern engines now send their own signals through sensors and data platforms. A driver, mechanic, or fleet manager can look at a screen and instantly know the engine temperature, fuel pressure, emissions status, and even how the turbocharger behaves under stress. Because of this technology, maintenance becomes strategic, not reactive.

As a result, Smart Sensors IoT Diesel systems are reshaping industries that depend on reliability. Trucks delivering goods across continents, tractors working through long harvesting days, and marine engines powering vessels at sea all benefit greatly from digital monitoring. Instead of shutting down without warning, today’s engines talk, learn, and respond. They serve as both machines and analytical partners, guiding decisions and preventing costly failures.

Therefore, the modern diesel world blends steel and data, mechanical strength and real-time intelligence. As digital adoption grows, this combination is no longer optional it becomes essential for staying competitive, efficient, and compliant with environmental standards.

Read More: The Science Behind Pressure Relief Foam

There are many reasons this shift matters. Fuel prices continue to rise. Environmental regulations become stricter each year. At the same time, equipment downtime can cost thousands of dollars per hour in sectors such as transport, mining, agriculture, and construction. Because of these pressures, Smart Sensors IoT Diesel technology offers a clear advantage.

Before digital technology, problems appeared only after damage occurred. Now, sensors detect tiny changes long before engines fail. For example, a vibration sensor can warn about bearing wear, a temperature sensor can signal cooling system trouble, and an exhaust analyzer can show emissions imbalance. Instead of surprise breakdowns, operators receive alerts early.

Moreover, real-time data helps improve fuel efficiency. When engines burn fuel more efficiently, companies save money while also reducing emissions. In addition, monitoring engine behavior allows technicians to adjust fuel injection, timing, and airflow for optimal performance.

Simply put: information makes engines smarter, safer, and more efficient. Because of that, Smart Sensors IoT Diesel systems support both business productivity and environmental responsibility.

Although this technology may feel complex at first, its core components follow a clear structure. Sensors gather information. Communication modules send it. Software analyzes it. Then operators take action based on live insights.

Major components include:

Pressure sensors for fuel and oil

Temperature sensors for coolant and exhaust

Vibration detectors on moving parts

Exhaust sensors for NOx, oxygen, and particulate levels

Turbo speed and boost sensors

GPS and telematics units

On-board diagnostic units (ECU monitoring)

Wireless data transmitters connecting to cloud dashboards

Because these components work together, Smart Sensors IoT Diesel systems help engines operate with awareness instead of guesswork. As a result, machines run smoother and fail less often.

To understand the value of this system, it helps to explore the sensors in detail:

These stabilize fuel delivery, ensuring the right amount reaches the cylinders. As a result, engines burn cleaner and use less fuel.

They help keep emissions low by monitoring combustion quality and after-treatment efficiency. Because of that, engines meet environmental standards more easily.

Coolant, oil, exhaust, and turbo temperature sensors prevent overheating and major damage.

These detect early warning signs of mechanical stress, helping avoid failures before they happen.

They optimize air-fuel balance, improving power output and reducing emissions.

Together, these tools create the intelligence layer of the Smart Sensors IoT Diesel ecosystem.

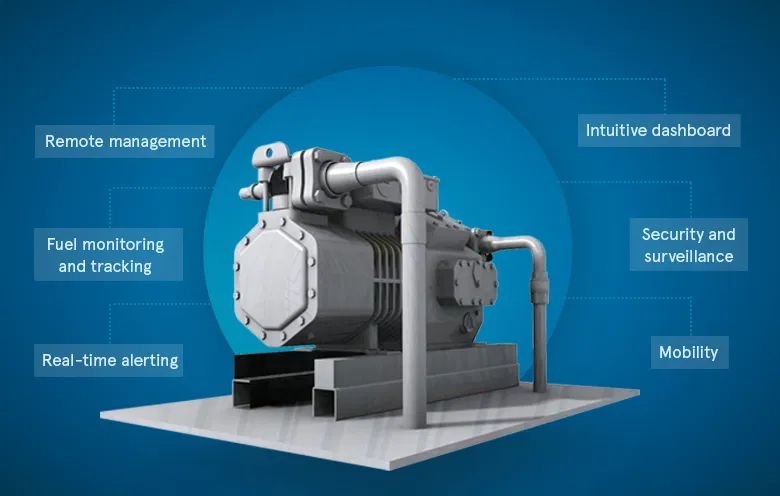

Sensors alone are not enough. They need connectivity. IoT (Internet of Things) links engines to digital platforms, allowing constant monitoring from anywhere. Therefore, a farmer at home, a fleet manager in an office, or a captain at sea can track performance from a tablet or phone.

IoT functions include:

Real-time engine health monitoring

Predictive maintenance notifications

Wireless diagnostics

Asset tracking and fuel reports

Operator behavior analysis

Remote engine shutdown or protection modes

Over-the-air software updates

Once engines can communicate, Smart Sensors IoT Diesel technology becomes a powerful operational tool.

Diesel engines matter in many fields. Because of this, smart systems have widespread impact.

Fleet managers check each truck’s performance remotely. Breakdown risk drops, schedules stay reliable, and fuel savings increase.

Tractors monitor soil conditions, engine load, and fuel efficiency. This improves harvesting and planting operations.

Bulldozers, excavators, and cranes operate in difficult environments. Smart monitoring reduces downtime on expensive equipment.

Machines work under extreme load. Therefore, early warnings prevent catastrophic failures underground or on open-pit sites.

Ships and vessels gain constant engine diagnostics, reducing risk at sea.

Across all these sectors, Smart Sensors IoT Diesel solutions create safer, longer-lasting, and more productive machines.

Even with new technology, people stay essential. Skilled technicians interpret data, perform repairs, and apply insights. Instead of removing jobs, digital engines create a new skill path. Mechanics learn diagnostics software, fleet managers analyze fuel reports, and operators understand engine alerts.

Because of this, the diesel workforce becomes hybrid: mechanical expertise combined with digital knowledge. This evolution improves service quality and increases technician value in the industry.

With Smart Sensors IoT Diesel adoption rising, training programs and workshops become crucial. As a result, the next generation of diesel professionals is more prepared, adaptive, and tech-literate.

Although progress is clear, challenges remain:

Cybersecurity and data protection

Cost of upgrading old equipment

Training technicians and operators

Internet access in remote work zones

Integration between different engine brands

Even so, the future looks promising. Soon, engines will self-diagnose with AI, schedule repairs on their own, and adjust fuel delivery based on climate and terrain. Because the world still depends on heavy-duty machines, Smart Sensors IoT Diesel will continue shaping industrial success for many years.

Diesel engines used to run on mechanical instinct alone. Today they run on insight, accuracy, and foresight. When machines report their health, they protect themselves and the operators who depend on them. When data drives decisions, efficiency becomes natural and downtime becomes rare.

Smart Sensors IoT Diesel systems prove that diesel power does not belong to the past — it belongs to the future. With each sensor, each alert, and each optimized fuel cycle, the engine becomes not just a machine, but a smart partner in productivity.

The modern diesel engine does not simply burn fuel. It learns, listens, and evolves — just like the industries it serves.

Diesel Specialists | Expert Engine Solutions for Diesel, Gasoline & More - Fleet operators and engine specialists now compare biodiesel…

Diesel Specialists | Expert Engine Solutions for Diesel, Gasoline & More - Turbochargers in diesel engines boost power and efficiency…

Diesel Specialists | Expert Engine Solutions for Diesel, Gasoline & More - Engineers across transport and industrial sectors increasingly rely…

Diesel Specialists | Expert Engine Solutions for Diesel, Gasoline & More - Diesel drivers face serious diesel cold weather starting…

Diesel Specialists | Expert Engine Solutions for Diesel, Gasoline & More - A neglected dirty diesel air filter quickly reduces…

Diesel Specialists | Expert Engine Solutions for Diesel, Gasoline & More The future of diesel specialists is changing rapidly as…